Filters must be designed to filter three different things, water, air and oil. Filters are very significant as they help cleanse dirt and particles or any other hazardous substances from the materials. But ultimately how do we really know if our filters are working properly and actually eliminating the correct set of users or accounts? This is where testing how well filters by Huirui work to perform. Basically, it helps us ensure our filters are filtering properly.

Filter performance testing provides a method to verify that filters are performing as expected. As a good example, filters that not works well allow harmful things to pass through them which eventually can cause some troubles for our health and environment. Test filters and make sure that they are working properly after every interval, as safe usage is the utmost priority. So, by keeping filters working well we can help keep ourselves and our environment clean and in good health.

Main Consideration for Filter Tests

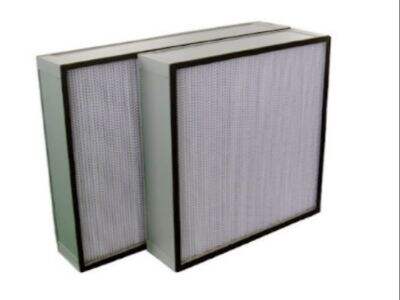

When you are testing filters, there are tons of instabilities. When it comes to High efficiency air filter, there are a few key things that can change how effective of a filter you end up with. This includes the type of filter material, pore size (how small particles must be to get trapped), surface area and flow rate.

Filter Media: The material of which a filter is made Various materials work well for various types of filtering.

Pore size is simply the size of holes in the filter. A finer hole hepa filter replacements will catch more little bits of stuff, but a wider hole might plug up less frequently.

The area is the amount of filter surface you have to get stuff clean. A larger area of the screen, obviously more particles.

The flow rate is the speed with which things can take place in this filter. If it is slow, this could indicate a problem.

These are all the elements that make a difference when testing how effectively some water filter cleans. A glass with small holes may be better at filtering out smaller particles than a cup with bigger ones, but the pores (holes) could also result in faster clogging and reduced flow rate. Well, that balance of how well it cleans and how fast/works.

Good filter testing rules

We need to establish rules and define criteria in order to test filters, properly. That means we should have a clear idea of what to look for and how to tell if specific filter works good, or not. Defining these terms makes it clear what each filter is being judged on, allows us all to arbitrate rather than just willy-nilly fight and tell one person they are wrong.

It is crucial to consider what the filter should do exactly. For example, a drinking Water filter will have different testing rules than an Air distributor which issued in factory to clean the air. One filter is not suitable to test against all.

The choice of how we test a filter is also paramount. There are numerous types of testing methods have been well used but each one comes with its own set of pros and cons. With the right methods you can check more aspects of a substance, some are better to see how big some particles are or some give information if there is any specific chemicals. It is critical to select the appropriate methodology in order to yield reliable results;

Techniques for Testing Filter Effectiveness

We can test filters in a large number of ways. Common methods are air flow resistance, aerosol penetration and particle counting. All these methods help us to know the different kind of filter performance.

The air flow resistance testing is conducted to determine the work needed by a filter for allowing air pass through. When the filter hepa h13 is clogged, or when it malfunctions and does not take in enough air at all into the combustion chamber because moisture becomes too much ravish for fuel release. This is something to keep an eye on.

During an aerosol penetration test, it is determined how much of a particular agent (e. g., virus or bacterium) can penetrate the filter. This testing allows us to establish how well the filter can capture certain dangerous particles, as this is essential in terms of safety.

It simply counts the number of particles in a certain size captured according to these filters. This method helps to know the performance score for a filter.

Filter Testing Compared to Standard Filter performance

If we are to compare various filters, then they should all be tested with the same methods. In other words, standardized testing protocols. The use of standardized methods is essential, as this enables comparison among results.

We are all testing each filter the same way but running their performance tests in a standardized manner. It can then be very difficult to really know which one works better, because we are testing the filters in completely different ways. This is another reason why a systematic approach to testing can be extremely helpful.

It also ensures that the testing is fair and accurate by having standardized tests. It is important because it gives us a clear idea that filters are being evaluated against the same criteria. The more reliable testing that we have, the more confidence in our results and conclusions.

In summary, test filter functionality to ensure proper execution of their function. There are a lot of things to consider when assessing the performance of filters including filter material, pore size, surface area and flow rate. In addition, specific test standards for tests of each material must be established and uniform standard methods need to be used in comparative evaluations among various filters. This helps keep us and our surroundings safe, we do this by making sure that, in order to have a clean environment, we can be confident-our filters are working.

EN

EN