×

×

The construction of the supporting factory building project of Huirui Purification - Liyang High-tech Zone Battery Industry Base is in full swing!

In this season full of hope, the builders of Huirui Purification have integrated vitality into every detail of their work, seized the key nodes of the project, and raced against time to update the project progress, interpreting responsibility and commitment with their actions.

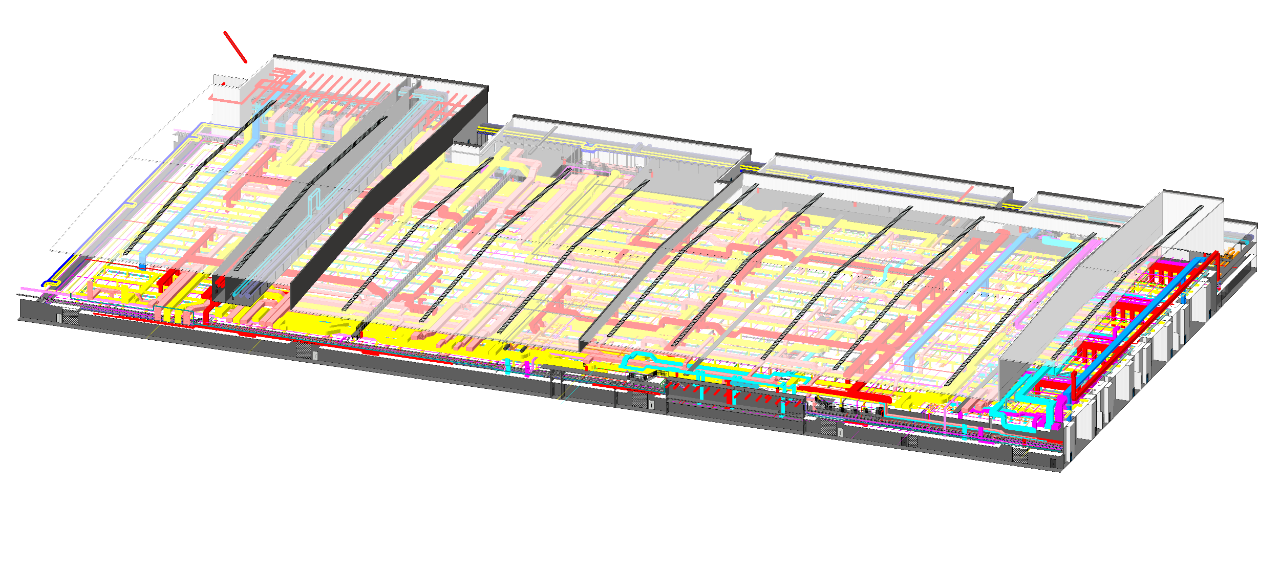

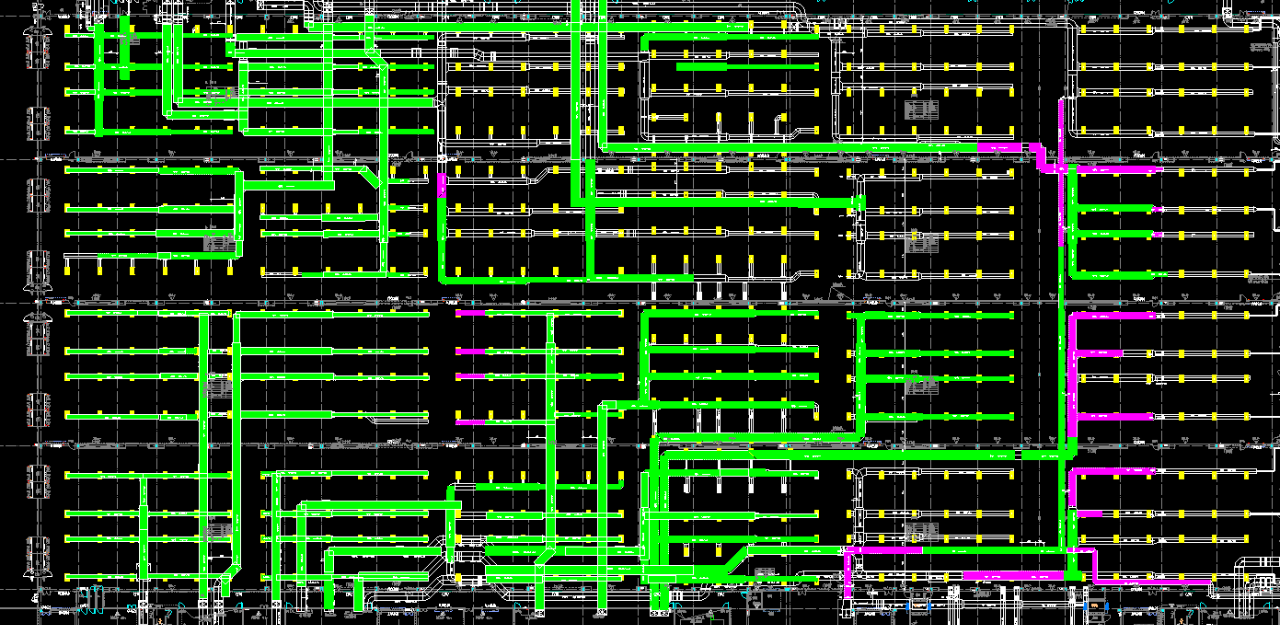

Recently, the mechanical and electrical general contracting project of the supporting factory building of Jiangsu Times Liyang High-tech Zone Battery Industry Base, undertaken by Huirui Purification, is located in Zhongguancun Science and Technology Industrial Park, Liyang City, Jiangsu Province, with a construction area of approximately 63,000 square meters. Construction content: It includes ventilation, air conditioning water pipelines, process pipelines, electrical, architectural and other specialties.

Every second counts to refresh the project progress

The bid was won on February 25, 2025. On February 26, 2025, the main project management personnel entered the site. Within five days, the construction preparations such as the material storage area, the air duct manufacturing area, and the project department office were completed. On March 10, the installation of the first batch of dehumidification and purification air ducts was completed. The entire project is expected to reach the medium supply by May 30 and meet the conditions for trial production. The word "fast" runs through the project construction.

Compared with traditional mechanical and electrical projects, this one involves the interweaving and integration of multiple professional systems such as air conditioning, electrical systems, process piping, and ventilation. How to achieve efficient collaboration among various construction teams and ensure high-quality performance throughout the entire process and across all specialties has become the key to the project's breakthrough.

Efficiently promote engineering construction "fast and good"

To achieve "fast and orderly" in a tight schedule and complex construction management, the key lies in "planning carefully before taking action". The project adopts the mechanical and electrical general contracting management model. By formulating the interweaving plan for all professional processes, precisely planning the "construction sequence, operation area division and professional connection", and based on the analysis of labor demand, scientifically allocating human, material and machinery resources, it not only ensures the efficient advancement of "parallel operation of multiple processes and coordination of multiple fronts", but also avoids resource waste and on-site chaos. Ultimately achieve the goal of "fast and good" engineering construction.

With strictness as the top priority, we must adhere to the red line and set an example in safety management

The project has fully implemented the safety production responsibility system, organized 57 safety education and training sessions (including new employee entry training), 49 safety education sessions for team leaders, 14 safety education meetings for all staff, and 1 fire drill. In total, more than 500 on-site workers have been educated.

Since entering the site, the project team has always adhered to the "Huirui people's" spirit of striving forward in the face of difficulties. With an unremitting fighting attitude and meticulous preparations, they have strictly controlled quality, rapidly improved efficiency, and raced against time, sparing no effort to promote the efficient performance of the project!